Welcome To MSK

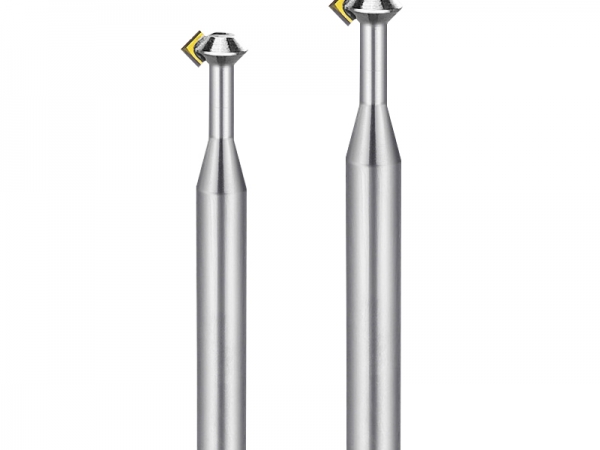

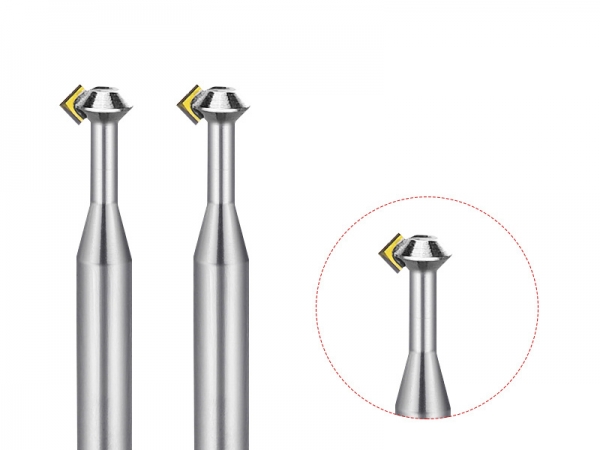

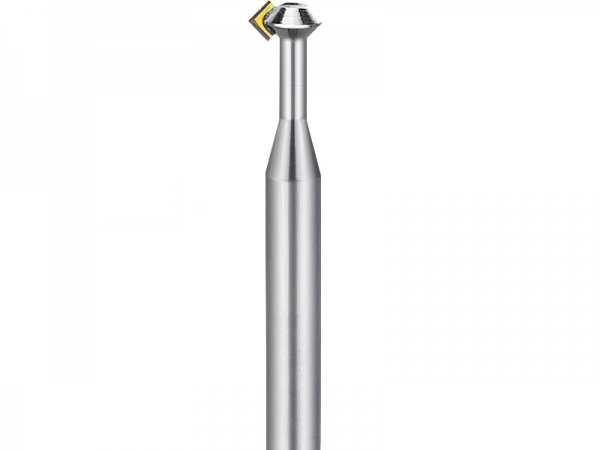

MCD High Gloss Chamfer Cutter For Gold

| Product Information | |||

| Origin | Tianjing, China | Type | Flat Milling Cutter |

| Brand | Msk | Whether To Coat | Uncoated |

| Series | Cutter Milling Cutter | Processing Range | Clocks And Watches, Copper And Aluminum Products, Mobile Phone Digital, Plexiglass (Acrylic) Industry, Etc. |

| Material | Tungsten Steel | Main Sales Areas | Africa, Europe, South America, Southeast Asia, North America, Northeast Asia, Middle East |

| Product Name | Single Crystal Diamond Up And Down Chamfering Knife | Handle Material | Tungsten Steel Or Alloy Material |

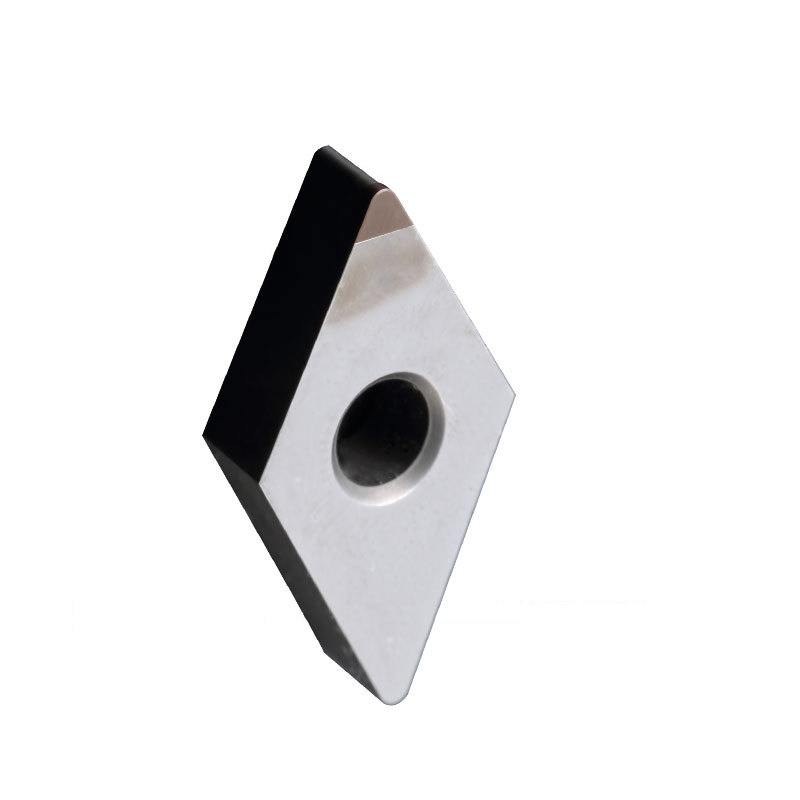

| Handle Material | Tungsten Steel Or Alloy Material | Blade Material | Customized Pcd, Single Crystal Diamond, Natural Diamond, Cvd |

| Tool Nose Width | 0.1-8.0mm | Rotating Speed | 5000-60000r/Min |

| Feed | 1500-5000mm/Min | Application Equipment | CNC And Other Machining Center Equipment |

| Processing Material | Mainly Used For High-Gloss Mirror Finishing Of Various Soft Metals, Gold, Silver, Copper, Aluminum Alloy, Zinc Alloy And Non-Metallic Materials, Acrylic, Pvc, Pc, Plastic And Other Materials | ||

Feature:

- Various materials can be customized with complete specifications.

- Strictly select imported diamonds, quality assurance, high finish.

- Tungsten steel shank is adopted, which has better stability.

- Wear-resistant and durable, widely used.

Precautions

Do not touch the cutter head with your fingers or anything. Although the hardness of diamond is very high, even a slight touch will damage the cutting edge and make the cutter unusable. Because a hard particle or even dust hitting the blade at high speed is enough to damage the blade.

If there is wear during use, it can be detected through a microscope. If it is within the refurbished range, it can be regrind and reused for many times to save costs. If it exceeds the measurable wear range, the tool needs to be replaced.

The MCD High Gloss Chamfer Cutter For Gold combines exceptional technology with top quality materials to deliver truly superior precision cutting performance.

With complete specifications and customizable options available this cutter stands out as one of the most versatile on the market today – able to tackle both hard metals like gold and softer ones such as plastics or wood without breaking a sweat! The incorporation of imported diamonds ensures a high end finish backed up by strict quality control measures put in place throughout every stage of production. Plus with a tungsten steel shank to provide extra stability and durability – this cutter is designed to last and can confidently handle any cutting task.

Professionals who rely on precision cutting techniques understand how crucial having quality tools can be when realizing flawless results in their workmanship process. The MCD High Gloss Chamfer Cutter For Gold presents itself as an exceptionally reliable option due to its state-of-the-art engineering and premium-grade materials used during production processes.

Achieving exquisite results has never been easier with this high-performance cutter – become convinced yourself today!

Products categories

Why Choose Us

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..