For hundreds of years, diamond engraving tools have been employed to craft exquisite designs on a multitude of materials from glass to valuable metals. Nowadays, diamond engraving is used to fashion diverse pieces from jewelery and decorative objects to prestigious trophies.

An engraving process that shapes eternal and precious configurations into various materials is aptly called diamond engraving. The tool used for it primarily consists of a set of diamond-tipped points, allowing the crafter to form majestic designs onto the surface of their choice.

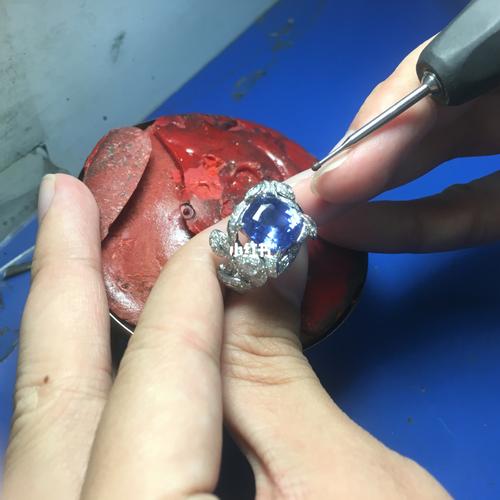

A clamp or a similar apparatus is used to secure the diamond engraver in place and provide stability while crafting a desired design. Some applications may even involve a motorized device that helps shift the tool accurately and completely.

A diamond burr is the most frequently used design tool when it comes to diamond engraving. This instrument can be used to fashion a multitude of shapes and patterns, reportedly capable of creating complex designs with deft finesse. Prepared with a sequence of small diamond-tipped points organised in a cylindrical or circular formation, moving the burr across the surface of the material produces grooves of a constant width and depth as predetermined by the tips.

For intricate designs and detailed marks, the combination of a diamond burr and diamond scribe is unbeatable. The scribe consists of a slim steel rod encrusted with an arrangement of diamond-tipped points, providing superior precision when etching into the surface of the material. With great finesse, this duo will craft superbly ornate and delicate engravings.

Those looking to make art out of their diamonds can make use of an array of engraving tools. From the classic diamond burr and diamond scribe to the more creative diamond chisel, diamond saw, and diamond graver, every tool has its own specialty. With these diverse implements in hand, one can produce intricate 3D designs, building wondrous works of art from precious stones.

To create a multitude of designs, textures, and shapes, diamond engraving tools are often utilized alongside other tools and techniques such as sandblasting and etching. With the combination of these methods, a wide array of outcomes can be achieved on the face of your chosen material.

The art of diamond engraving requires a certain level of finesse and expertise to attain the desired outcome. Mastery of the right tools is essential in order to achieve sound results and put together an attractive design.

Prices for diamond engraving tools can drift across a wide spectrum, depending on the quality of the diamond and which tool is being used. Usually, as the diamond’s classiness rises, so will the cost of the instrument in question.

Diamond engraving is an art form that allows creators to etch intricate and unique patterns into various materials. By utilizing the right tools and techniques, artisans can make indelible, beautiful designs that are sure to be appreciated for years to come.

For those looking to etch intricate designs and patterns, diamond engraving tools are the optimal choice. Crafted using some of the toughest materials available, such as diamonds, these engravers can provide a high level of precision to any hard material with little difficulty. Amongst the areas where diamond engraving tools are particularly popular is within industries such as watchmaking, jewelry making, and engraving.

Comprising of its two essential components, diamond engraving tools are designed to create intricate patterns and designs. The diamond-tipped bit is crafted from a robust diamond-coated carbide material which provides it with the needed durability to sustain the task, while its motion is governed by a mechanical device like a drill press that drives the tool for the desired effect.

The craft of diamond engraving can be precise and delicate work. To create a design, the bit first needs to be set with the correctdepth and pressure. The bit must be slowly guided along the material for accuracy, and the speed and pressure of the bit should be adjusted to avoid potential damage to the diamond. All of this needs to be done to achieve the desired end-result.

Hard metals aren’t the only materials that can be given a creative touch through diamond engraving tools- even softer substances such as wood and plastic can offer exquisite designs. By utilizing the diamond-tipped bit, intricate patterns and decorations can be carefully etched into these materials, adding an air of beauty to a range of products.

Crafting jewelry, designing intricate watch components, or adding detail to items made from hard and soft materials: these are all projects that benefit from diamond engraving tools. These tools can bring a level of precision, both in design and durability, that many other tools cannot reach. It is no surprise that diamond engraving tools have become an essential part of the toolbox for countless industries.

Keep safety a priority when you wield that diamond engraving tool. The bit is very sharp and can lead to serious injury if used carelessly. Additionally, make sure to use the device the right way to guarantee your design or emblem will turn out exact and unblemished. Remember to comply with all instructions that accompany the tool for absolute safety.

No matter the industry or project, diamond engraving tools are an essential component. Able to carve out intricate designs with ease on a variety of surfaces, from metal and stone to wood and plastic, these tough tools can withstand the test of time and keep going. However, when working with these machines, precautions should still be taken to safeguard yourself from any potential accidents. So make sure to take all the necessary steps to ensure a safe work environment.

Related Product

Diamond Turning Tools Outer Jewelry R Cutter

Product Information Origin Tianjing, China Material Tungsten Steel Brand Msk Type Half Round Key Milling Cutter Product Name Single Crystal Diamond Side Edge Arc Milling Cut […]

Single Crystal Diamond Polishing Cutter

Origin Tianjing, China Shank Diameter 6 (mm) Brand MSK Blade Change Method The Diamond Is Welded To The Cutter Body As A Whole Material Single Crystal Diamond (MCD) Scope Of […]

MCD Turning Tool Mirrow Finish R Cutter

Product Information Product Name Single Crystal Diamond Lower Chamfering Inner R Cutter Brand MSK Handle Material Tungsten Steel Blade Material Customized Pcd, Single Crysta […]

MCD Polishing Cutter for Gold Silver

Product Information Origin Tianjing, China Whether To Coat Uncoated Brand MSK Unit Weight 0.3kg Tool material Tungsten steel bar imported from Germany Product Size Shank Dia […]

MCD High Gloss Chamfer Cutter For Gold

Product Information Origin Tianjing, China Type Flat Milling Cutter Brand Msk Whether To Coat Uncoated Series Cutter Milling Cutter Processing Range Clocks And Watches, Copp […]

CVD/PVD/MCD Gold Jewelry Diamond Engraving Cutter

Parameter Product Name Single Crystal Diamond Carving Cutter Rotating Speed 10000-30000r/min Tool Nose Width 0.1-6.0mm Feed 1500-5000mm/min Blade Material Single Crystal Dia […]

Lathe Bits MCD High Gloss Chamfer Tool

Product Information Origin Tianjing, China Cutting Edge Form Straight Edge Brand MSK Material Single Crystal Diamond Chamfer Angle 30°-180° Type Angle Milling Cutter Minimum […]

Post time: 2023-07-13